Research programme

Corrosion protection

In the field of corrosion protection our research is focused on the following topics:

Materials and coatings for biomedical applications

Prolongation of the average age and an active life-style in the senior age have led to the constant increase in the number of various implants and devices, e.g. orthopaedic, cardiovascular, and ophthalmological implants. In the present paper we will be dealing with orthopaedic implants, primarily total hip and knee replacements. Osteoarthritis is the most common type of arthritis affecting millions of people worldwide, usually middle-aged and older people. This is a non-inflammatory degenerative joint disease characterized by the breakdown of the joint's cartilage. The diseased hip joint is replaced by a joint replacement, the functionality of the joint is recovered and the pain is reduced. The total replacement of joint has become one of the most successful elective surgical procedures in modern medicine. The long-term performance of hip replacements is largely determined by the process of aseptic loosening, as being the most common reason for revision surgery.

Long-term stability and performance of each biomedical implant is largely dependent on the type of materials used for its manufacture. The most commonly used metallic bio materials are stainless steel, cobalt- and titanium-based alloys.

A specific property of titanium-based materials is their osseointegration ability, which is based on the formation of bone cells and mineralized bone matrix on the titanium surface. The effect of osseointegration can be increased by increasing surface roughness and consequently surface area. This can be achieved by means of various processes encouraging bone in-growth and providing enhanced fixation, such as surface roughening, a porous coating, using wire as fiber-metal coatings, employing a beaded surface or plasma-sprayed surface, etc. In addition to osseointegration, another property of material surface, i.e. the ability to resist of bacteria attack, is important. Implant-related infection is a serious complication which requires a long-term antibiotic treatment and, very often, implant removal. This is related to personal suffering for the patient and also high medical costs.

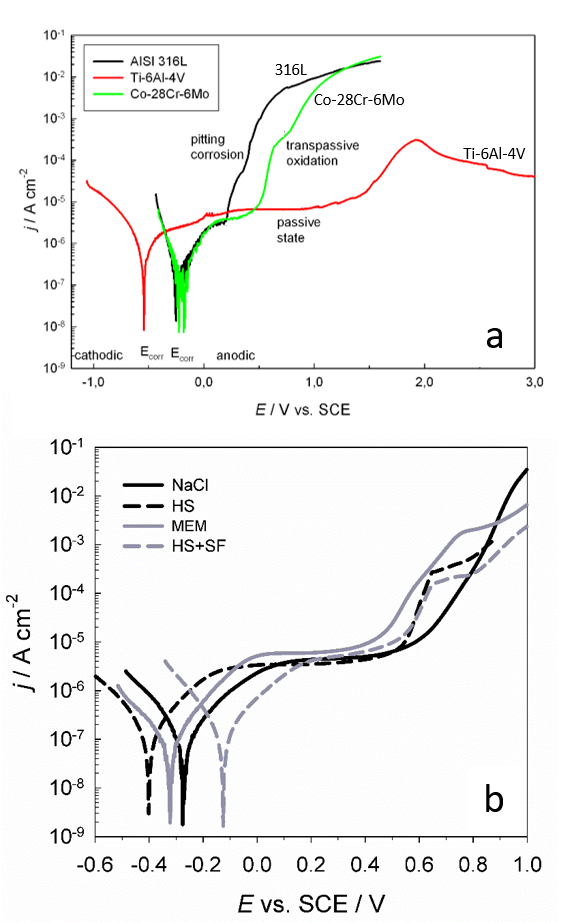

Figure: (a) Potentiodynamic polarization curves for stainless steel, Co-28Cr-6Mo, Ti-6Al-4V, and Ti-6Al-7Nb alloys recorded in Hanks balanced salt solution. dE/dt = 1 mV/s. Regions of passivity, pitting corrosion, and transpassive oxidation are denoted. (b) Potentiodynamic polarization curves for recorded for Co-28Cr-6Mo alloy in different simulated physiological solutions: 0.9 wt% NaCl (NaCl), Hanks balanced salt solution (HS); minimum essential medium (MEM) and HS containing 1 mL synovial fluid (HS+SF). dE/dt =1 mV/s. Reprinted from the publication by I. Milošev, Electrochim. Acta, 2012, 78, 259-273.

Publications related to materials and coatings for biomedical applications

Y. Hedberg, M. Žnidaršič, G. Herting, I. Milošev, I. Odnevall Wallinder, J. Biomed. Mater. Res. B, 2019, 107B, 858–867

I.Milošev, Corrosion, 2017, 73, 1496–1509.

D. Covaciu Romonţi, J. Iskra, M. Bele, I. Demetrescu, I. Milošev, J. Alloys Compd., 2016, 665, 355–364.

N. Cotolan, M. Rak, M. Bele, A. Cör, L.M. Muresan, I. Milošev, Surf. Coat. Technol., 2016, 307, 790–799.

I. Milošev, Surface treatments of titanium with antibacterial agents for implant applications, In: Biomedical and Pharmaceutical Applications of Electrochemistry Surface, Modern Aspects of Electrochemistry, editor Stojan S. Djokic, Springer, vol. 60, 2016.

M. Kulkarni, A. Mazare, E. Gongadze, Š. Perutkova, V. Kralj-Iglič, A. Iglič, I. Milošev. P. Schmuki, M. Mozetič, Nanotechnology, 2015, 26, 062002.

I.Milošev, B. Kapun, P. Rodič, J. Iskra, J. Sol-Gel Sci. Technol., 2015, 74, 447–459.

Y. Konttinen, I. Milošev, R. Trebše, P. Rantanen, R. Linden, V.-M. Tiainen, S. Virtanen, Metals for joint replacement, In: Joint replacement technology, editor Peter A. Revell, Woodhead Publishing, Cambridge, England, 2008 1st edition, 2014, 2nd edition.

I.Milošev, G. Žerjav, J. Calderon Moreno, M. Popa, Electrochim. Acta, 2013, 99, 176–189.

I. Milošev CoCrMo alloy for biomedical applications, In: Biomedical applications, Modern aspects of electrochemistry, vol. 55, editor Stojan S. Djokic, Springer, 2012.

I. Milošev, Electrochim Acta, 2012, 78, 259–273.

I. Milošev, B. Kapun, Mater. Sci. Eng. C, 2012, 32, 1068–1077.

I. Milošev, B. Kapun, Mater. Sci. Eng. C, 2012, 32, 1087–1096.

I.Milošev, Pure & Appl. Chem., 2011, 83, 309–324.

S. Virtanen, I. Milošev, E. Gomez-Barrena, R. Trebše, J. Salo, Y. Konttinen, Acta Biomaterialia, 2008, 4, 468–476.

I. Milošev, T. Kosec, H.-H. Strehblow, Electrochim. Acta, 2008, 53, 3547–3558.

A. Kocijan, I. Milošev, B. Pihlar, J. Mater. Sci. Mater. Med., 2003, 14, 69–77.

I. Milošev, H.-H. Strehblow, Electrochim. Acta, 2003, 48, 2767–2774.

I. Milošev, H.-H. Strehblow, J. Biomed. Mater. Res., 2000, 52, 404–412.

I. Milošev, M. Metikoš-Huković, H.-H. Strehblow, Biomaterials, 2000, 21, 2103–2113.

Projects related to materials and coatings for biomedical applications

Improvement of functionality of biomedical and engineering materials, Slovenian-Argentinian cooperation 2012–2014 (BI-AR/12-14-010) dr. Ingrid Milošev / dr. Silvia M. Ceré (INTEMA, Corrosion Division, Mar del Plata)

Survivorship of total hip replacements as a function of type of bearing surfaces, J3-0052 2008–2011, project leader: dr. Ingrid Milošev

The effect of bio-environment on the stability of biomedical metallic materials, J1-2243, 2009–2012, project leader: dr. Ingrid Milošev

MATERA: Improvement of resurfacing hip implants with DLC, TiO2 and DLC-p-h nanocomposite coatings dr. Ingrid Milošev, coordinator dr. Veli-Matti Tiainen, Orthon, Helsinki, Finland, 2007–2010